The denim industry has long reigned as one of the most unshakable sectors of the fashion world. A wardrobe staple throughout the decades, no one really questioned the power of the blue jean basic until the emergence of the athleisure trend graced the catwalks several years ago.

This market shift, along with growing consumer interest in more sustainably, ethically produced clothing, is forcing the denim industry to take stock, innovate and quickly evolve.

Last week, Avery Dennison RBIS invited a stellar panel of industry visionaries to discuss the Future of Denim in Downtown Los Angeles. A global leader in apparel branding, labeling, packaging, embellishments and RFID solutions, Avery Dennison RBIS hosted the event at the company’s DTLA Customer Design and Innovation Center.

Focus was placed on consumer trends, expert insights, and increased sustainability in the retail industry. The panelists discussed the unique findings from Avery Dennison RBIS’ recent consumer and denim insights research, including consumer preferences impacting purchase intent across the denim industry and the influence of the ever-growing athleisure trend.

Chaired by Amy Leverton, former Denim Director at WGSN and author of acclaimed Denim Dudes, guests were treated to insights and foresight from Adriano Goldschmied, Founder & Creative Director of Goldsign; Miles Johnson, Creative Director at Patagonia; David Hieatt, Founder of Hiut Denim; and Marco Lucietti, Global Marketing Director at Isko Denim.

Adriano Goldschmied and Amy Leverton

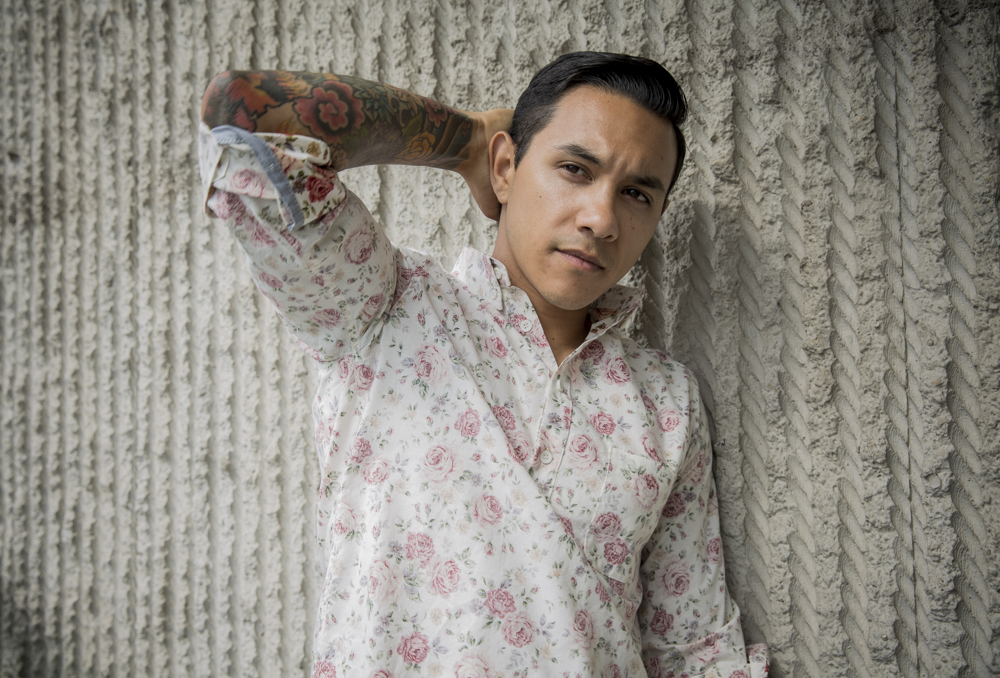

The importance of fit was immediately emphasized in response to Amy’s opening question about consumer loyalties. Branding will always be important in a competitive market but the panel discussed how consumers primarily make repeat purchases due to finding the right fit.

Miles Johnson and David Hieatt

Technological advancement in stretch denim has certainly upped the fit game, but the industry competes with the comfort levels offered by sportswear brands, a segment that is now crossing over to also offer denim lines.

The panel agreed that the denim purists will always want their selvage denim, but the industry is in need of innovators. There is no equivalent of Nike in the denim world and the space is ripe for change.

In recent years, knit has challenged the traditional woven technique for making jeans; subsequently opening up the market.

“The present always looks like the most important thing, but there is no present without thinking and preparing for the future. ”

Growing consumer awareness and the increasing demand for supply chain transparency, are putting pressure on an antiquated manufacturing system. When asked who should be pioneering the change towards a more conscious fashion industry, the response was that it can’t simply be one company or brand.

It has to be a joint effort as ultimately the responsibility rests on all of our shoulders.

“The responsibility comes back to us, the consumer. It’s cool to care about the planet we live on.

”

Standards are slowly rising and the digital era allows us to be as informed as we choose to be. Consumer demand could effectively force apparel companies innovate or die. With a notable rise in jeans made from organic cotton, alternative design and manufacturing methods are becoming increasingly accepted and expected.

“Make them well and make them look good.

There needs to be a massive cultural shift; it’s not a trend, it’s the right thing to do.

”

Cost is of course an issue, to both companies and consumers. If the price tags remain prohibitively high, consciously made denim will remain a commodity for the minority. An undeniable source of pollution to our planet, the industry does not currently have economies of scale on organic cotton. It is a highly political topic that requires a revolutionary answer.

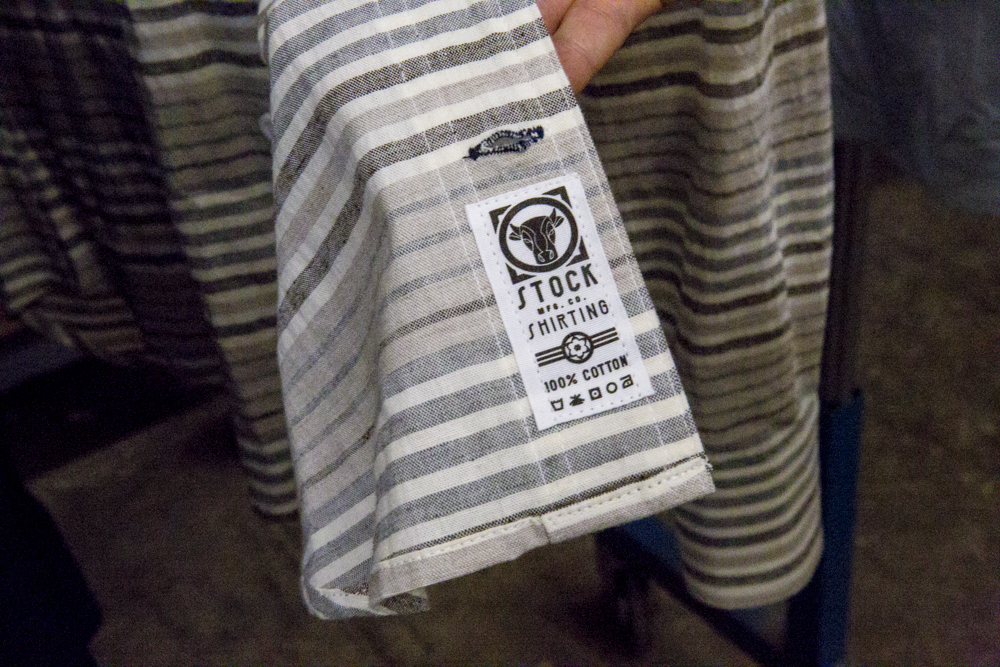

Marco Lucietti

““Jeans are a democratic product. We should not position responsible jeans as a question of price. We need to make them accessible for everyone.

”

As the panel dispersed, guests returned to the party, customizing t-shirts and gorgeous Isko Denim totes, and generally bonding over their collective love of the blue stuff.

In addition to denim, an inescapable factor brought us together that evening: a shared passion for creativity and innovation. And so to my favorite quote of the evening...

“I want to sell to ideas people. Creative people wear jeans; people that change the world wear jeans.

”

To find out more visit rbis.averydennison.com

Or email: maria-teresa.ortiz@averydennison.com

@AvyDenRBIS

#BeyondThePatch

Creative Direction & Writing: Jennie McGuirk

Photography: Betsy Winchell