Left to right: Tim Tierney (Product Development) Jim Snediker (CEO) Jason Morgan (Operations Director) Mike Morarity (Creative Director).

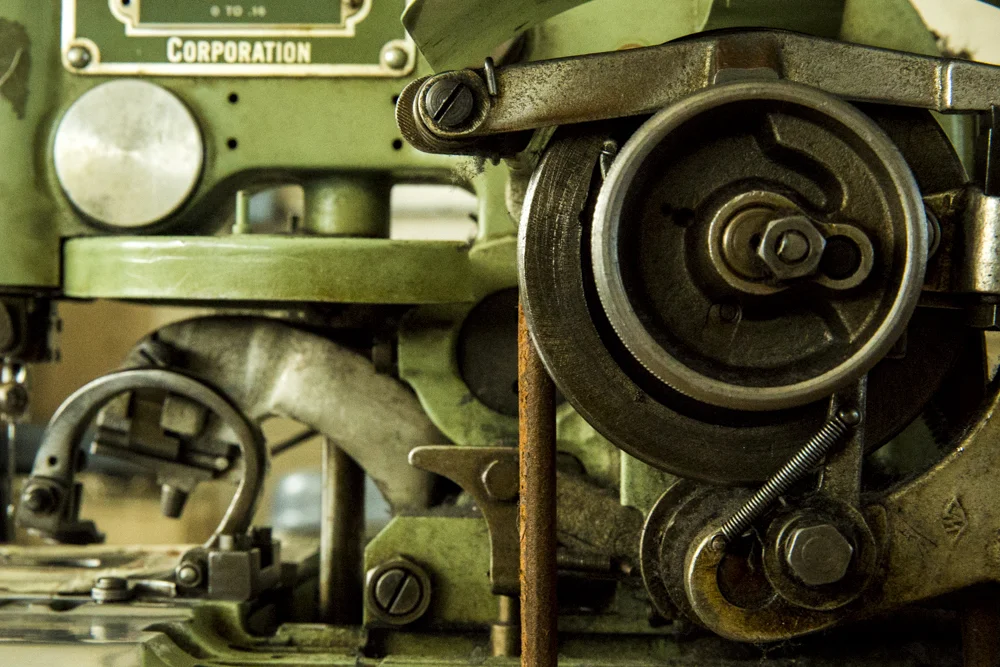

The Stock Manufacturing Company story began just two years ago, as an entrepreneurial group of guys joined forces to launch a premium, menswear brand out of a fifty-year-old factory in the heart of Chicago.

Each bringing their own skill sets and industry perspectives to the table; they are pioneering a vision to create jobs, support the local economy and keep prices as competitively low as possible, on a range of clothing that they themselves proudly wear.

By combining the time-tested factory infrastructure with the explosive power of digital media, the team has found a way of successfully leveraging both traditional and modern business practices to create a sustainable model for American manufacturing.

The brand draws its name from the legendary Chicago Stock Yards that not only played a defining part in the city’s history, but also went on to inspire advances in American industry, such as Henry Ford’s auto assembly line.

The stock market was the epicenter for white-collar innovation as well as the backbone of blue-collar job creation.

Our logo, the bullhead, is Mike’s interpretation of an old restaurant logo where all the high rollers in Chicago went when the Stock Yards were still big.

We’ve pulled a lot of inspiration from the architecture and the Bauhaus movement of Chicago; everything that we do comes back to the Mid-Western mentality.

The masculine aesthetic of the brand is woven throughout: from the design decisions that go into the clothing, to the website and various marketing materials.

Emphasis is placed on the functionality of each product as much as the style aesthetic, giving the brand a distinct visual identity in the marketplace.

Mike comes from an industrial product design background, keeping functionality in mind with a lot of the designs, while Tim is from a product development background so will look at it from a salability aspect. The product has to appeal to the market but still stay true to the brand as we want to make sure that our pricing stays consistent.

The team also designs with the core customer in mind, as a third of sales are in Chicago itself, followed by California and New York.

It’s the major cities in America but Chicago isn’t exactly fashion forward, so we’re trying to ease into fashion forward product but with focus on stable pieces.

As the demand for domestic-made products continues to grow, Stock Mfg Co. is tapping into the menswear market with its own style of modern basics.

There’s a lot of hometown pride and we’re one of the only local factories that makes menswear in the city. The market isn’t as nearly developed as it is in NY or LA, which helps our visibility and exposure.

However, rather than marketing themselves as a Made In America brand, they just consider it to be an integral part of how they do things.

We want our products to be able to stand against any clothing brand. We are half the price of comparable brands that are made in the USA, so that’s where we fit into the discussion, as we’re trying to bring quality and craftsmanship to a broader appeal.

There are clear advantages of having a local workforce who are there at the factory for the whole process. The current drawback however, is the lack of trained labor, as the factory is certified as a Mil-Spec quality manufacturing facility and finding people with that level of expertise is not as easy as it might seem.

As we grow, we’re going to have to start finding more operators; there will be a need for in-house training and apprenticeships down the line.

We’ve held training programs in the past where 75 -100 people came through and maybe only one of those people became a full time operator. It takes sewing skills but also the ability to be able to sit there and focus.

Initially testing a crowdsourcing model that supported up and coming designers, the team was finding it difficult to gain traction as a fledgling company. The breakthrough moment came in the form of a collaborative project with a group of well-connected bloggers, stylists and photographers based in New York.

These Brand Evangelists promoted a genuine social media dialogue, which in turn validated the product and saw the brand scale to new heights.

That led to us dropping the crowdsourcing aspect and going into making limited run collaborations. It was a good way for us to scale up initially, and it was also when we figured out our customer.

A lot of our customers are trendsetters, so they’re out there representing the brand, and getting exposure for us.

We’re good at what we do in terms of knowing what products are going to sell, and making the right amount of inventory so that our overhead is still low. We started with single pieces and have grown to capsule collections.

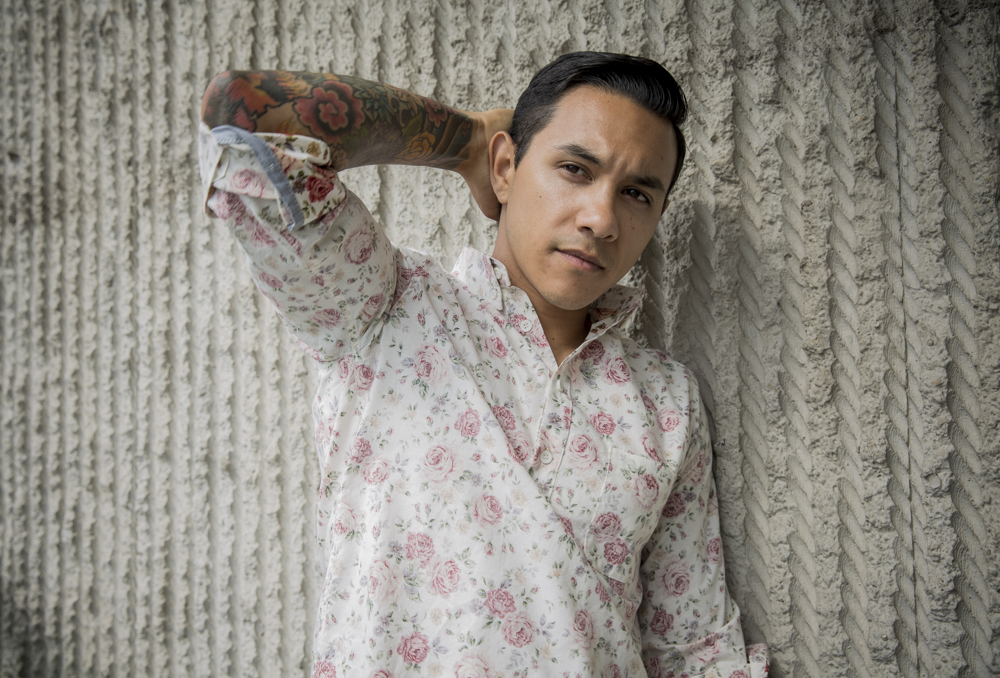

Featured Model, Steven Sampang, is one of team's most prolific Brand Evangelists:

I've been following the Stock Mfg guys since they put their first shirt into production and have been hooked on their brand ever since.

It's fascinating to watch these guys doing something that no other clothing brand seems to know how to do; and that's do shit the right way. As I get older and invest in the threads I buy, I'm realizing that it's nearly impossible to get U.S., let alone Chicago-made pieces without paying designer prices.

These guys are proving that there's no reason why local, ethically conscious, high quality, and affordable clothing can't all fit in the same sentence; or did I just prove that for them?

By remaining lean and nimble in their business structure and practice, they have identified various marketing channels, which double up as customer acquisition.

A big part of having an online business is that you can see who your customers are and you maintain contact with them rather than relying on them to walk into a store. So far our entire customer acquisition model has been through digital media, and it’s been very organic. The pillar of our business is the agility of being online with the backbone of the factory where we can enact changes quickly.

The setting of tangible milestones has been key to maintaining an ambitious pace for business growth, as well as encouraging focus on what ideas work and what needs to be dropped. By paying close attention to online metrics the team has been able to design, test and iterate not only the product but also the entire business model, allowing market feedback to inform their choices.

We’ve had a bottle of 23-year-old bourbon that we’ve been waiting to open at a major milestone, but we keep hitting the milestones and decide to wait for another one before opening it.

Hitting each goal is really satisfying, and each one creates more momentum towards the next one. Getting feedback from clients actually wearing the stuff we make is really motivating.

Another breakthrough moment came as Stock secured several B2B contracts for high-profile Chicago brands.

Goose Island was bought by a large company but wanted to maintain their Chicago identity, so they came to us to show that they are still a local craft beer brewery with local business in mind.

We’ve also created uniforms for restaurants Alinea and Next. They’d been sourcing stuff from France with a 6-month lead-time; we came in and cut their costs in half and developed stuff exactly to their specs. We’re providing a service and a value that wasn’t really out there.

The collaborative angle of their model places emphasis on delivering individual design solutions for each client’s needs. This isn’t a one-size fits all shop; Stock forms a partnership with each of its clients, in order to provide custom solutions that make the difference.

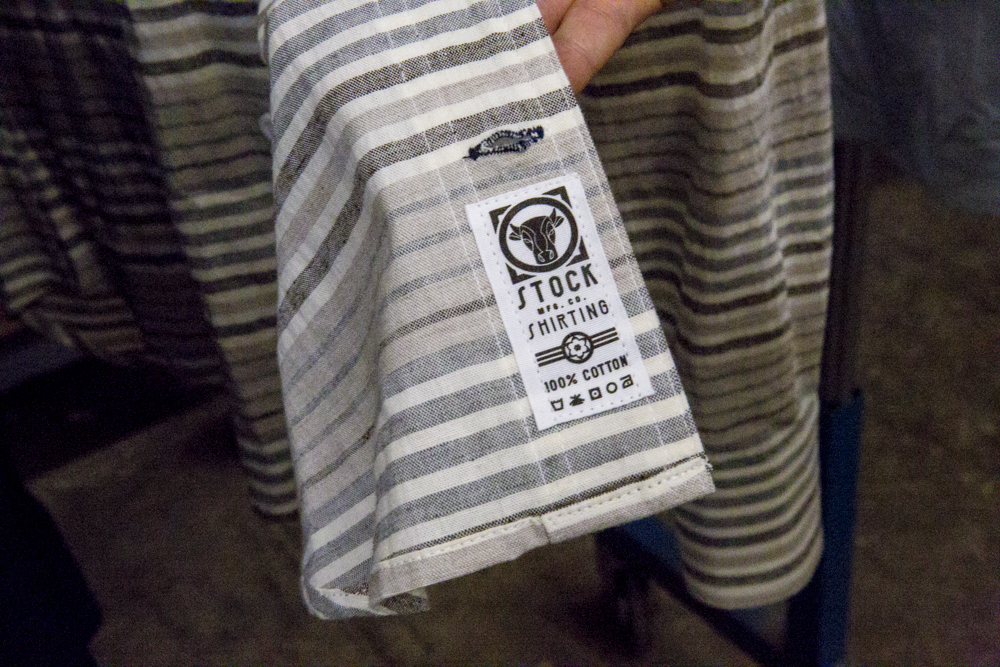

Not only do they deliver a better product and save their clients time and money by producing locally, but the team is also able to market directly to a target demographic through the labels that are stitched into every uniform.

Whether it be for the Stock in-house label, a creative collaboration or a client company uniform; each Stock product is “branded” with a unifying logo that represents quality, trust and a shared vision for sustainable growth.

Visit Stock's online store

Or email: info@stockmfgco.com

Spread the love by referencing Brilliant Collective

Creative Direction & Writing: Jennie McGuirk

Photography: Betsy Winchell

Model: Steven Sampang